How it's made

Limited Resources is a product Canadian company what ships it products all over the world. All our products are made from high quality components which will pass the test of time. In order to bring this high quality to each and every unit our manufacturing process is executed in house. In house manufacturing allows us to ensure zero defect rate and fast product feature development.

Manufacturing process being with sourcing metal from Dell Metals. Once metal is purchased it is sent to our lasing and stamping plant. Metal sheets are laser cut and sent to the stamping factory.

On to chemical bath, and powder coating is the third stage of manufacturing. Once pay box timer are prepared for powder coating then a special electric painting process call powder coating is applied. By powder coating help to prevent rust and increase pay box time life in the real world, over simply painting enclosures. The final part of powder coating is to harden the colored powder coat by blasting with heat in the parts furnace.

Final phase is electrical assembly and testing.....

Manufacturing process being with sourcing metal from Dell Metals. Once metal is purchased it is sent to our lasing and stamping plant. Metal sheets are laser cut and sent to the stamping factory.

On to chemical bath, and powder coating is the third stage of manufacturing. Once pay box timer are prepared for powder coating then a special electric painting process call powder coating is applied. By powder coating help to prevent rust and increase pay box time life in the real world, over simply painting enclosures. The final part of powder coating is to harden the colored powder coat by blasting with heat in the parts furnace.

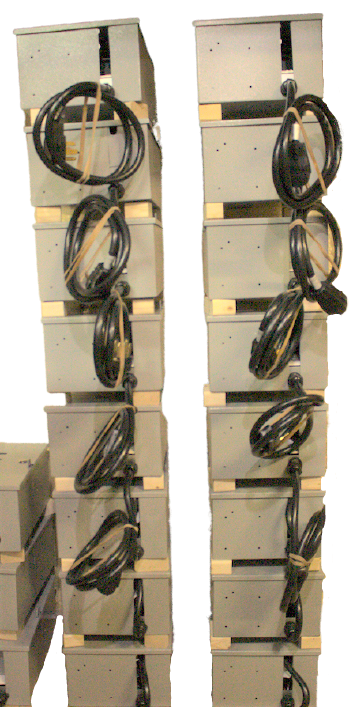

Final phase is electrical assembly and testing.....